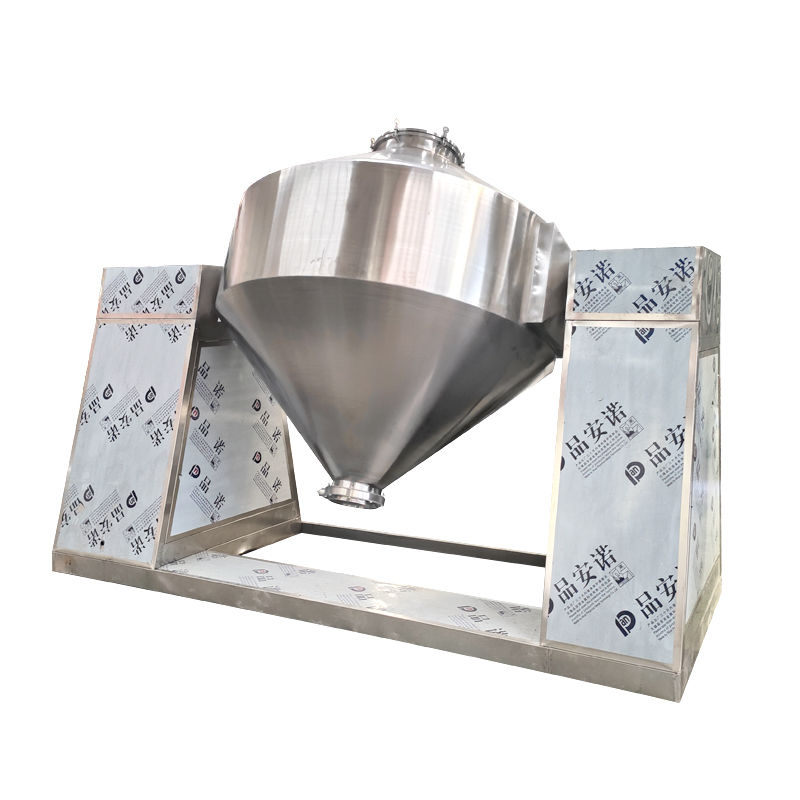

Mikser podwójnego stożka

Opis produktu

Mikser podwójnego stożka to szeroko stosowany sprzęt do mieszania proszku w branżach takich jak farmaceutyki, żywność i chemikalia. Jego podstawowa struktura składa się z dwóch stożkowych cylindrów połączonych ze sobą, które obracają się wokół osi poziomej napędzanej silnikiem. Zawiera wysoką wydajność mieszania, bez martwych zakątków i minimalną pozostałość. Ponadto może być wyposażony w funkcje takie jak karmienie próżni i rozpylanie rozpylania zgodnie z wymaganiami. Jest odpowiedni do mieszania materiałów suchych i półprzewodnikowych i działa wyjątkowo dobrze w scenariuszach, w których wymagana jest wysoka dokładność mieszania i płynność materiału.

Zasada pracy

Po uruchomieniu sprzętu silnik napędza komorę mieszania utworzoną przez dwa stożkowe cylindry, aby obracać się ze stałą prędkością wokół osi poziomej. Materiały w komorach stożkowych są ciągle podnoszone na pewną wysokość, gdy cylindry obracają się, a następnie naturalnie podlegają wpływowi grawitacji. Podczas tego procesu struktura stożkowa powoduje, że materiały tworzą różnorodności podczas ich zejścia. W połączeniu z siłą ścinającą i efektem dyfuzyjnym generowanym przez obrót cylindrów różne rodzaje proszków lub materiałów ziarnistych mogą się w pełni kontaktować i być równomiernie zmieszane bez wymuszonego mieszania, ostatecznie osiągając pożądany efekt mieszania.

Charakterystyka produktu

1. Wysoka jednolitość mieszaniny: Za pomocą struktury stożkowej oraz efekty ścinania i dyfuzji wytwarzane przez obrót materiały mogą osiągnąć bezproblemowe mieszanie, szczególnie odpowiednie do materiałów pudrowych lub ziarnistości o dobrej płynności. Dokładność mieszania może zaspokoić potrzeby większości zastosowań przemysłowych.

2. Minimalne uszkodzenie materiału: Bez żadnych wymuszonych elementów mieszania materiały mieszają naturalnie pod wpływem grawitacji, zmniejszając kompresję, kruszenie lub zużycie kruchych materiałów.

3. Niska pozostałość: Ściana wewnętrzna jest gładka, a konstrukcja stożkowa jest rozsądna. Podczas rozładowania materiały można szybko opróżnić przez grawitację, co powoduje niską resztkową ilość wewnątrz sprzętu, co jest wygodne do czyszczenia i zmiany rodzajów materiałów.

4. Prosta operacja: Struktura jest stosunkowo prosta. Efekt mieszania można dostosować, kontrolując prędkość i czas obrotu. Stopień automatyzacji można zwiększyć zgodnie z wymaganiami.

5. Silna zdolność adaptacyjna: Konfigurowanie funkcji, takich jak karmienie próżni, rozpylanie, ogrzewanie / chłodzenie kurtki itp. Można go rozszerzyć na suszenie, reakcję i inne scenariusze, odpowiednie dla wielu branż, takich jak medycyna, żywność i inżynieria chemiczna.

Aplikacja

1. Wysoka jednolitość mieszaniny: Struktura stożkowa umożliwia swobodny przepływ materiałów, zmniejszając stagnację, szczególnie odpowiedni dla proszków/cząstek o podobnej gęstości. Wysoka jednorodność mieszaniny: Struktura stożkowa umożliwia swobodny przepływ materiałów, zmniejszając stagnację, szczególnie odpowiedni dla proszków/cząstek o podobnej gęstości. Wysoka jednorodność mieszaniny: Struktura stożkowa umożliwia swobodny przepływ materiałów, zmniejszając stagnację, szczególnie odpowiedni dla proszków/cząstek o podobnej gęstości.

2. Niska zawartość resztkowa: gładka ściana wewnętrzna + bez deadu dead rogu, resztki po rozładowaniu jest znacznie niższe niż w przypadku wyposażenia z mieszającymi łopatkami, odpowiednie dla materiałów o wysokiej wartości.

3. Dobra wydajność uszczelnienia: W pełni zamknięta struktura zmniejsza wyciek pyłu, spełniając czyste standardy produkcyjne branż, takie jak medycyna i żywność.

4. Prosta konserwacja: brak złożonych komponentów, niski wskaźnik awarii i niższe koszty konserwacji niż sprzęt do wiosła lub ostrza.

5. Niższe zużycie energii: zmieszane przez grawitację i rotację, nie ma potrzeby silnika o dużej mocy, a koszt operacyjny jest bardziej ekonomiczny.

6. Szerokość zastosowania: odpowiednia do suszących proszków/cząstek i niewielkich ilości mieszania cieczy, z niewielkim uszkodzeniem kruche materiały.

Parametr produktu

| Model |

W-300 |

W-500 |

W-1000 |

W-1500 |

W-2500 |

W-4000 |

W-6000 |

W-8000 |

|

Zdolność produkcyjna

(kg/czas)

|

150 |

250 |

500 |

750 |

1250 |

2000 |

3000 |

4000 |

|

Pełna głośność

(miernik sześcienny)

|

0,3 |

0,5 |

1 |

1.5 |

2.5 |

4 |

6 |

8 |

|

Czas miksowania

(min)

|

4-8 |

4-8 |

6-12 |

6-12 |

6-12 |

6-15 |

6-15 |

6-15 |

|

Moc silnikowa

(KW)

|

1.1 |

2.2 |

3 |

4 |

5.5 |

7.5 |

11 |

15 |

| Prędkość cylindra (RPM) |

15 |

15 |

12 |

12 |

12 |

10 |

10 |

10 |

|

Wymiar

(L*w*h)

|

1680*650

*1600

|

2080*750

*1900

|

2150*850

*2100

|

2300*1600

*3100

|

2500*1000

*2450

|

2980*1580

*2800

|

3500*1800

*3000

|

3980*2000

*3200

|

| Waga (kg) |

310 |

550 |

800 |

950 |

1650 |

1880 |

2350 |

2680 |

Schemat linii produkcyjnej

1. Pracownik zwolnij torbę na stacji zrzucającej torbę bez kurzu, ponieważ w maszynie znajduje się kolektor kurzu, więc pył

2. Maszyna sitowa usunie materiał grudki lub dużej wielkości, umożliwiając tylko przepływ materiału mniejszego rozmiaru do systemu przenoszenia

3. Przenośnik próżniowy przenosi materiał do lejka buforowego lub zbiornika magazynowego, czekając na mieszankę

4. Kiedy trzeba się wymieszać, podajnik próżniowy rozpoczyna pracę, przetransportować materiał z lejka do podwójnego miksera stożkowego

5. Po mieszaniu mieszany materiał zostanie przetransportowany do maszyny do pakowania, zapakowany zgodnie z ustawioną masą, a następnie uszczelniony torba

W systemie cały proces przekazywania jest uszczelniony w celu zapewnienia higieny i bezpieczeństwa.

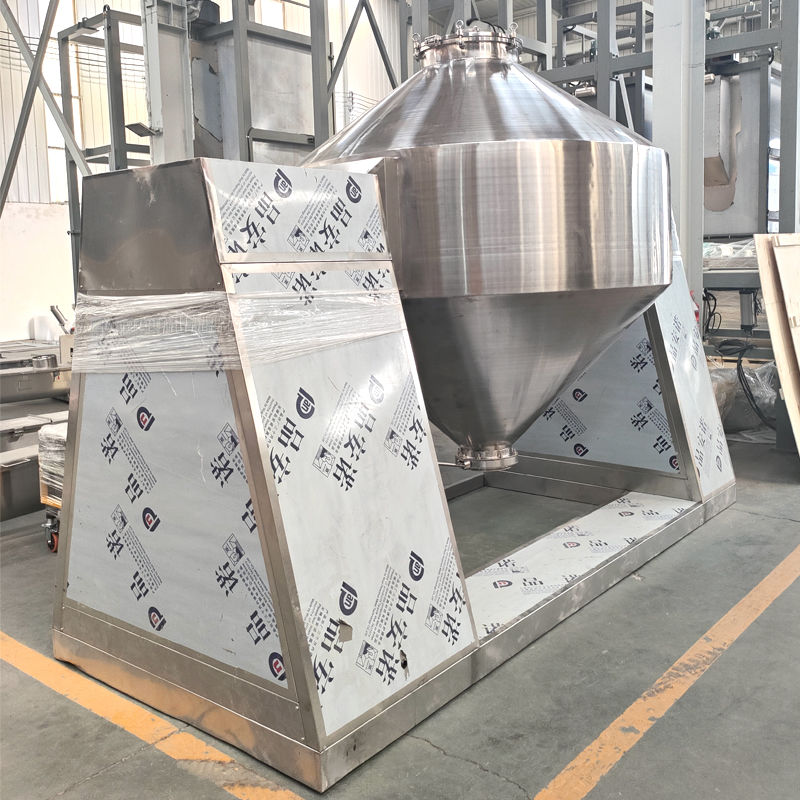

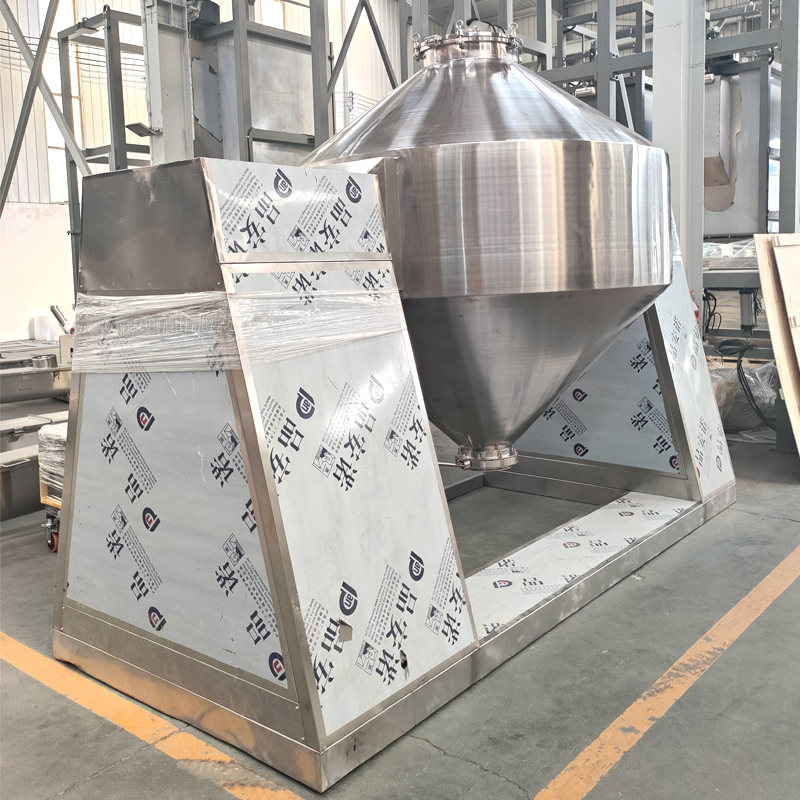

Wyświetlacz szczegółów

Wyświetlacz produktu

Opakowanie i wysyłka

Dlaczego warto nas wybrać

O nas

Profil firmy

Od 13 lat specjalizujemy się w produkcji sprzętu do badań i przekazywania. Chin wibrujący branża branży najlepszych. Dopasowaliśmy i OEM dla wielu dużych firm. W tym na świecie najlepszy producent wibrujący, SWECO, USA, mamy OEM dla jego regionu w Chinach. A nasze produkty są często eksportowane do Australii, Tajlandii, Indonezji, Nowej Zelandii i innych krajów.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!