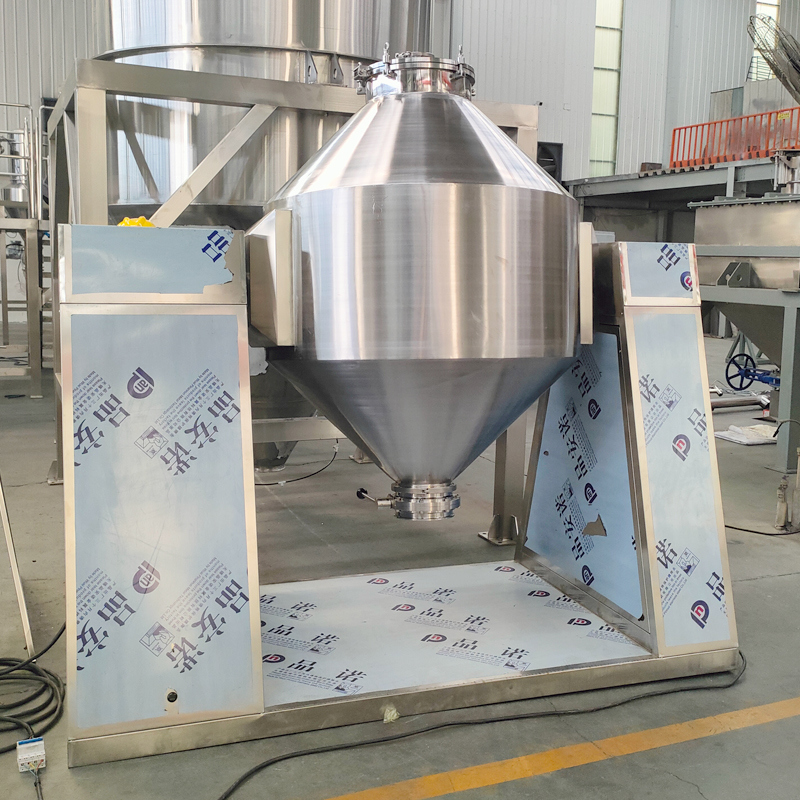

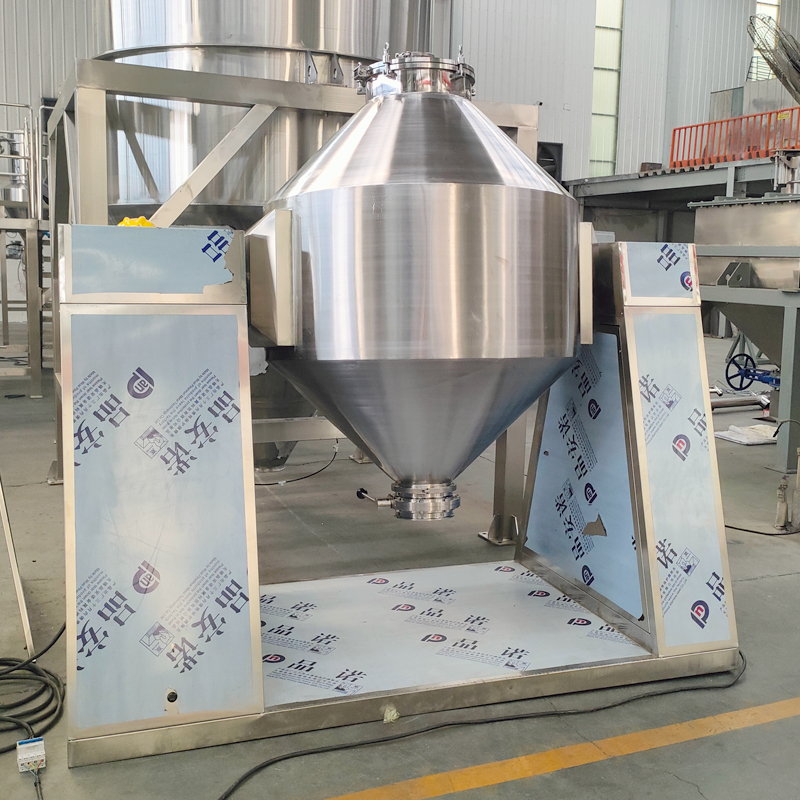

Dwukrotny mikser stożkowy

Opis produktu

Mieszalnia podwójnie stożkowa jest wydajnym sprzętem do mieszania proszku. Jej głównym elementem jest podwójnie stożkowy zamknięty pojemnik.doskonała wydajność uszczelniająca (która może skutecznie zapobiegać zanieczyszczeniu pyłem)Jest odpowiedni do proszków i materiałów ziarnistych o dobrej płynności. Jest szeroko stosowany w dziedzinie farmaceutyki, żywności, chemikaliów, materiałów budowlanych itp.,i może stabilnie spełniać wymagania dotyczące jednolitego mieszania materiału w produkcji seryjnej w różnych gałęziach przemysłu.

Zasada działania

Podstawową zasadą działania mieszarki podwójnej jest osiągnięcie przymusowego konwekcji i mieszania materiałów poprzez dyfuzję poprzez ruch pojemnika:Podwójny stożkowy zamknięty pojemnik obraca się wokół poziomej osi środkowejPodczas obrotu materiały w cylindrze wznoszą się do określonej wysokości z powodu ściany pojemnika, a następnie spadają i rozpraszają się z powodu grawitacji.podwójna konstrukcja stożkowa prowadzi materiały do przemieszczania się do przodu i do tyłu i przeplata się między końcami a środkiem pojemnika, stale doświadczając wymiany pozycji i wzajemnej penetracji.przerywa początkowy stan dystrybucji materiałów i umożliwia jednolite mieszanie różnych proszków lub cząstek składowych.

Charakterystyka produktu

1. Wyższa mieszanka: Wysoka jednolitość, struktura podwójnej stożki bez martwych kątów, nadająca się do wielokomponowanych i bardzo zmiennych materiałów proszkowych i ziarnistych;

2Wysoki poziom bezpieczeństwa: konstrukcja zamkniętego pojemnika, zapobiegająca wchłanianiu wilgoci, zanieczyszczeniu i wyciekowi pyłu z materiałów, spełniająca wymagania dotyczące czystości;

3Łatwa konserwacja: Prosta struktura bez skomplikowanych elementów mieszania, łatwe czyszczenie, mniej pozostałości, mniej części zużywanych i niższe koszty konserwacji;

4Szeroki zakres zastosowań: może obsługiwać materiały proszkowe i ziarniste, z urządzeniem rozpylającym, które może również mieszać niewielką ilość płynu, obejmującym wiele gałęzi przemysłu;

5Niskie zużycie energii: Niska prędkość obrotu pojemnika, delikatny ruch materiału, niskie zużycie energii i mniejsze uszkodzenie właściwości materiału.

Zastosowanie

1. Mieszanie równomiernie: Brak martwych kątów. Dwukrotna konstrukcja stożkowa pomaga materiałom w pełni mieszać się, z wysoką jednolitością, odpowiedni dla proszku i materiałów granulowanych;

2. Dobrze uszczelnione: zaprojektowane zamknięte pojemniki zapobiegają zanieczyszczeniu pyłem i wyciekom materiałów, spełniając wymagania branży czystej;

3Łatwe w obsłudze: prosta struktura, szybkie rozładowywanie, mniej pozostałości, brak potrzeby skomplikowanego demontażu do codziennej konserwacji;

4. Szeroki zakres zastosowań: Można go wyposażyć w systemy regulacji temperatury i próżni, odpowiednie do ogólnych i specjalnych wymagań procesów wielu gałęzi przemysłu;

5Niskie straty: brak szybkich części mieszanych, mniejsze zużycie materiału, stabilne właściwości, niski hałas urządzeń, długa żywotność.

Parametry produktu

| Model |

W-300 |

W-500 |

W-1000 |

W-1500 |

W-2500 |

W-4000 |

W-6000 |

W-8000 |

|

Pojemność produkcyjna

(kg/czas)

|

150 |

250 |

500 |

750 |

1250 |

2000 |

3000 |

4000 |

|

Cała objętość

(metr sześcienny)

|

0.3 |

0.5 |

1 |

1.5 |

2.5 |

4 |

6 |

8 |

|

Czas mieszania

(min)

|

4-8 |

4-8 |

6-12 |

6-12 |

6-12 |

6-15 |

6-15 |

6-15 |

|

Moc silnika

(KW)

|

1.1 |

2.2 |

3 |

4 |

5.5 |

7.5 |

11 |

15 |

| Prędkość obrotowa cylindra (RPM) |

15 |

15 |

12 |

12 |

12 |

10 |

10 |

10 |

|

Wymiar

- Nie, nie, nie.

|

1680*650

*1600

|

2080*750

* 1900

|

2150*850

*2100

|

2300*1600

*3100

|

2500*1000

*2450

|

2980*1580

* 2800

|

3500*1800

* 3000

|

3980*2000

*3200

|

| Masę (kg) |

310 |

550 |

800 |

950 |

1650 |

1880 |

2350 |

2680 |

Diagram linii produkcyjnej

1Pracownik uwalnia worek na stacji zrzucania worków wolnych od pyłu, ponieważ w maszynie znajduje się zbieracz pyłu, dzięki czemu pył leci.

2Maszyna do sitowania usunie grubość lub duży materiał, umożliwiając jedynie przepływ mniejszych materiałów do systemu przenośnego

3Przenośnik próżniowy przenosi materiał do buforowej lub magazynowej łodzi, czekając na mieszankę

4. Kiedy trzeba mieszać, podkładacz próżniowy rozpoczyna pracę, transportować materiał z hopper do mieszarki podwójny stożek

5Po zmieszaniu mieszany materiał zostanie przetransportowany do maszyny pakowania, pakowany zgodnie z ustaloną masą, a następnie uszczelniony worek

W systemie cały proces transportu jest zamknięty w celu zapewnienia higieny i bezpieczeństwa.

Wyświetlacz szczegółów

Wyświetlacz produktu

Opakowanie i wysyłka

Dlaczego wybrać nas?

O nas

Profil przedsiębiorstwa

Specjalizujemy się w produkcji sprzętu do przesyłania przez 13 lat.W tym największy na świecie producent ekranów wibrujących.Nasze produkty są często eksportowane do Australii, Tajlandii, Indonezji, Nowej Zelandii i innych państw.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!